Electronic boards: from invention to production

Per restare aggiornato entra nel nostro canale Whatsapp

The introduction of electronic boards has profoundly transformed the electronic devices sector, thanks to their efficiency and ability to reduce the size of the equipment. These components, in fact, manage the internal functions of a wide variety of instruments, helping to make them very compact, lightweight and high-performance .

Nowadays, they are essential elements both in advanced technologies used in industrial settings and in everyday devices used in domestic and professional contexts.

The possibility of integrating them easily has accelerated the development of increasingly advanced solutions , improving performance, reliability and versatility in many application fields. As a result, the role of electronic board manufacturers has also grown significantly, constantly engaged in the development of increasingly smaller and more powerful devices .

What are electronic cards?

As already mentioned, the electronic board is a fundamental element within any electronic system, as it represents the union between hardware and software capable of managing and coordinating the functioning of a machine.

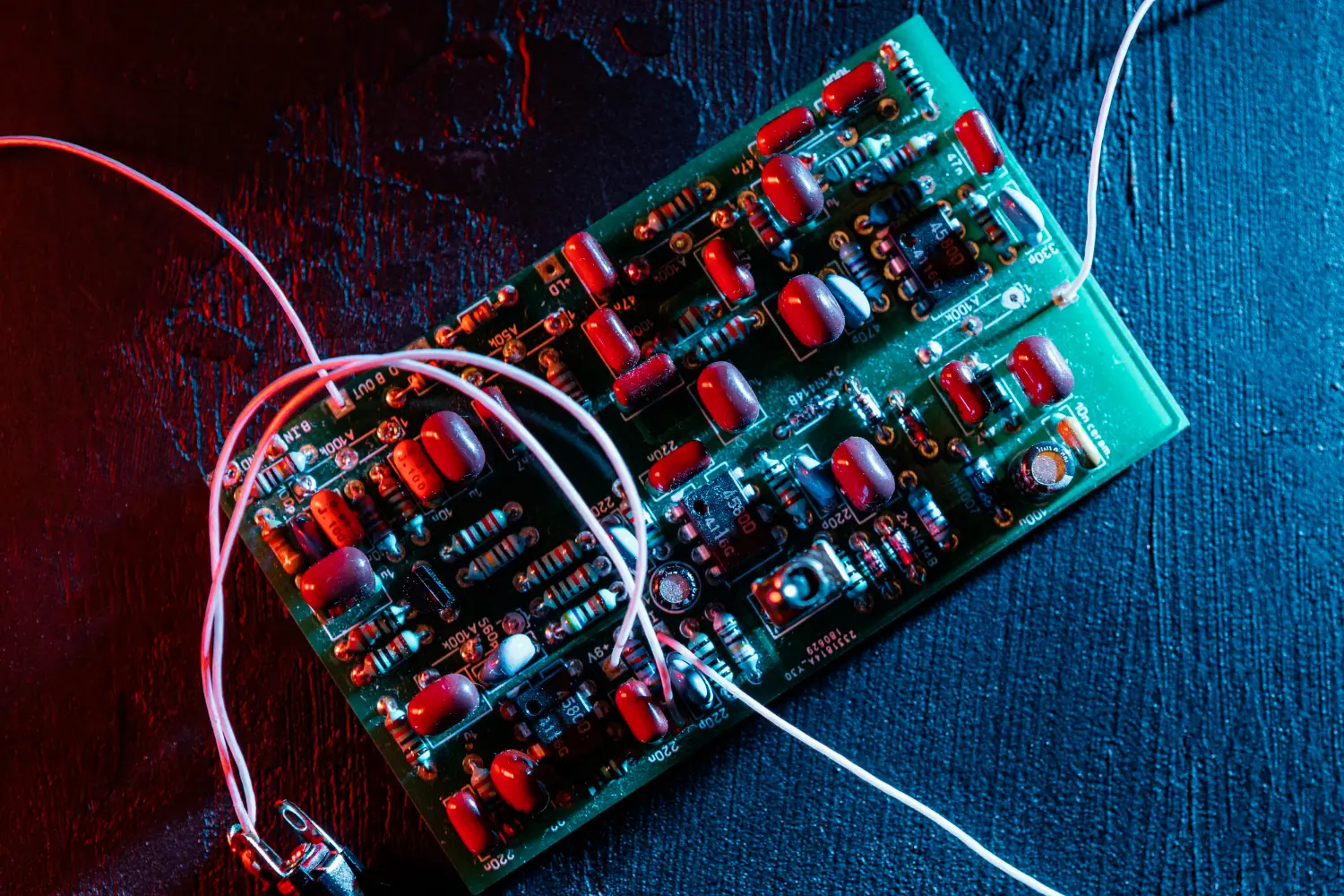

It is a printed circuit board on which components are mounted that allow communication between the different electrical parts of the device, improving its efficiency and performance. In practice, the electronic board acts as a real brain , capable of activating and regulating the mechanical part of the machine itself.

It is present in a wide range of devices , from the most common household appliances such as ovens, washing machines and computers, to complex industrial systems such as automated machines or UPS .

How they are produced

To produce electronic boards, we start from the design phase, managed by expert engineers and designers. The process begins with the customer's request , who describes his needs to the manufacturer. If there are no particular difficulties, we move on to the design using CAD (Computer Aided Design) software.

Once this is done, we move on to the creation of prototypes , which are then tested to exclude any errors. If the tests are successful, we continue, otherwise the project is modified. The actual production is divided into four main phases.

The first involves the assembly of the components , which can be done manually or automatically, depending on the chosen technology. A visual inspection is then carried out to detect any aesthetic or structural defects. This is followed by a series of electronic tests to verify the correct functioning of the circuits. Finally, a final test is performed to ensure that the board operates as expected in real-world conditions.

Who invented them?

The history of electronic circuit boards begins in 1903 , when inventor Albert Hanson filed a patent for a device consisting of a flat conductor mounted on a multi-layered insulating panel .

Although Hanson's invention was very different from modern circuit boards, it probably represented the starting point for the development of today's PCBs (Printed Circuit Boards) and electronic circuit boards.

His idea of using insulating and conducting materials arranged in a specific way, in fact, laid the foundation for the technological evolution that led to the creation of modern electronic circuit boards, fundamental to the functioning of countless electronic devices in use today.